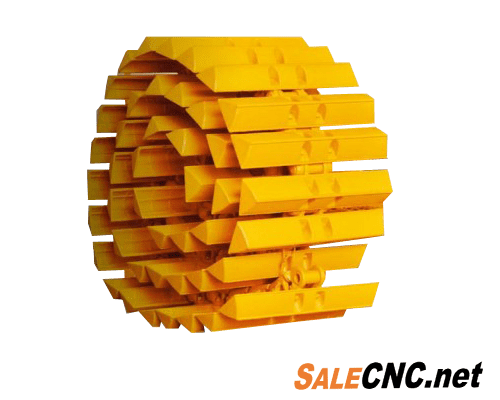

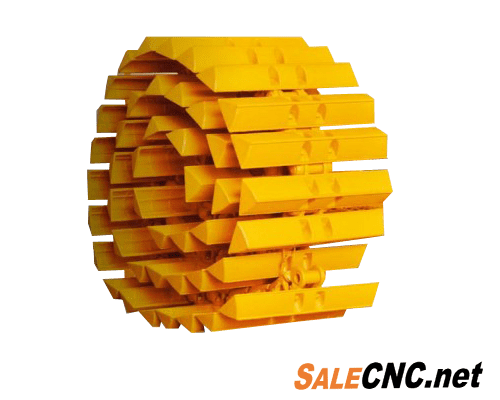

Excavator Chain Track ASSY Y

Our Excavator Chain Tracks are designed for compatibility across top global brands, ensuring your machinery performs at its best no matter the make. Precision-engineered and crafted from high-quality, durable materials, our tracks can be seamlessly integrated with excavators from Caterpillar, Komatsu, Hitachi, Volvo, John Deere, Sany, JCB, Kobelco, Liebherr, and Hyundai.

Why Choose Our Excavator Chain Tracks?

Our chain tracks are built to withstand the toughest conditions, providing superior traction, stability, and durability across various terrains. These tracks meet the demands of heavy-duty applications, making them ideal for construction, mining, and other industrial environments.

Benefits of Our Excavator Chain Tracks:

- Wide Compatibility: Our chain tracks are tailored to fit major excavator brands, ensuring smooth integration and reducing downtime for replacements or upgrades.

- Enhanced Durability: Made from high-grade steel and treated to resist wear, our tracks endure the harshest environments, delivering longevity and minimizing maintenance costs.

- Improved Stability and Traction: Whether you're working on soft ground, rugged landscapes, or steep inclines, our tracks provide superior grip and support, reducing slippage and enhancing machine performance.

- Cost-Effective Performance: By choosing our chain tracks, you're investing in quality components that help extend the life of your excavators, lowering overall maintenance costs and boosting productivity.

- Available for Leading Brands: Our tracks are specifically engineered to match the specifications of industry-leading brands, ensuring each track perfectly complements the power and precision of Caterpillar, Komatsu, Hitachi, Volvo, John Deere, Sany, JCB, Kobelco, Liebherr, and Hyundai machines.

Excavator Chain Track: The Backbone of Heavy Machinery

Excavator chain tracks are essential components in heavy-duty machinery, providing stability, mobility, and support across rugged terrains. Unlike wheels, chain tracks distribute an excavator's weight over a larger surface area, ensuring enhanced traction and preventing sinking in softer ground like mud, sand, or gravel. Built from high-grade steel, these tracks are made to withstand the rigorous demands of construction sites, mining areas, and demolition fields.

Key benefits of excavator chain tracks include:

1. Enhanced Traction and Mobility

Chain tracks grip the ground more effectively than wheels, providing reliable movement across difficult surfaces. This feature is especially valuable for excavators operating on slopes, slippery ground, or loose soil. The track's design allows it to “grab” the surface, minimizing slippage and enhancing the machine's stability, even in challenging environments.

2. Durability and Strength

Excavator chain tracks are designed to bear the weight of the machine while resisting wear from rocks, debris, and other abrasive surfaces. They are made from heat-treated steel links connected with robust pins and bushings, which give them resilience and longevity under intense working conditions. Routine maintenance, such as lubrication and tension adjustments, helps keep these tracks functional for extended periods.

3. Load Distribution for Ground Protection

The wide base provided by chain tracks spreads the machine's weight, reducing the pressure on each inch of ground. This is crucial on softer or sensitive surfaces, where traditional wheeled machinery might cause deep ruts or other types of damage. With chain tracks, excavators can perform heavy-duty tasks with minimal impact on the underlying surface, making them ideal for environmentally sensitive areas.

4. Maintenance and Repairs

Excavator chain tracks, though durable, do require periodic maintenance to ensure peak performance. Maintenance routines include checking for wear and tear on individual track links, ensuring optimal tension, and lubricating the moving parts. Parts like rollers, idlers, and sprockets are essential for smooth track operation and may need replacement over time. Many excavators are designed with easy-access points to facilitate quick repairs or part replacements, minimizing downtime.

5. Types of Chain Tracks

Excavators can come with different types of chain tracks, such as rubber and steel tracks. Rubber tracks are quieter and suitable for indoor or finished surfaces, while steel tracks provide rugged durability and are best for harsh outdoor environments. Choosing the right type of track is crucial for maximizing productivity and minimizing machine wear.

6. Environmental Considerations

Modern chain tracks are often designed with sustainability in mind. Some manufacturers focus on reducing environmental impact by producing recyclable materials or by creating modular parts that can be replaced individually rather than replacing the entire track.

By incorporating excavator chain tracks, operators ensure that their machines have the stability, strength, and flexibility needed to tackle complex construction challenges.

**custom made products, please contact sales to confirm spec and price**

***Please contact the sales representative before purchasing to confirm specifications and price.***

**This is a made-to-order item**

Please contact Line Official: @Nulex @salecnc

Reviews

There are no reviews yet.