Why must SALECNC How is it different from competitors?

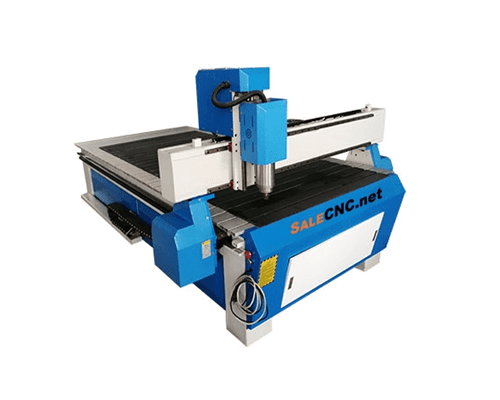

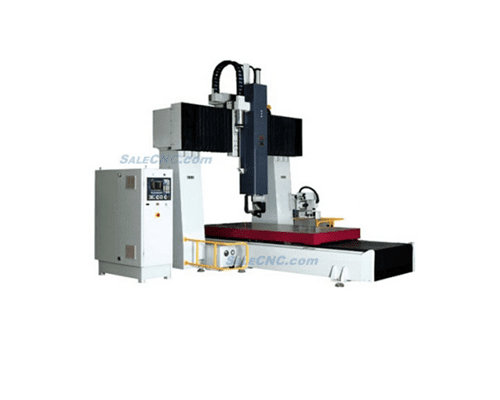

Our company has been in operation for over 40 years. We are a professional manufacturer and supplier of CNC machines for CNC Router, CNC Laser, CNC Plasma, CNC Lathe. We export quality machines to more than 50 countries all over the world. We can also design and manufacture CNC machines according to customer's requirements (Custom made) to make our customers use better and save money.

At CNC, we buy parts in bulk, which means lower costs than others who buy in small quantities. This allows us to provide our customers with the best possible prices. We serve customers in over 50 countries worldwide.

Our engineers are from America and Japan. Our systems are fast and efficient, and we are committed to producing quality and reliable machines.

Please check our factory: About Us (Click here)

CNC MACHINES What do we sell?

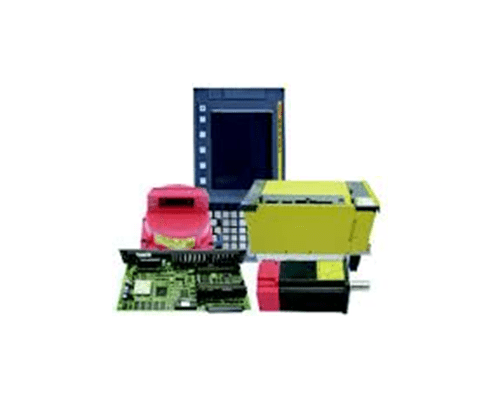

Engraving machine, iron cutting machine, lathe, bending machine, folding machine, acrylic cutting machine, CNC equipment, servo motor, stepping motor, sign making machine, CNC machine, engraving machine, laser machine, CNC milling machine, computer cutting machine, computer engraving machine, sign engraving, house sign engraving, mold making engraving, PCB drilling, mold making engraving machine, wood engraving machine, plastic engraving machine, plastic sheet engraving machine, electric engraving machine, computer engraving machine, computer engraving machine, ivory engraving machine, amulet engraving machine, amulet engraving machine, Buddha image engraving machine, sacred object engraving machine, engraving machine for sale, cnc engraving machine, wood cutting machine, plastic sheet cutting machine, acrylic sheet cutting machine, aluminum cutting machine, wood cutting machine, plastic sheet milling machine, acrylic sheet cutting machine, aluminum cutting machine, wood milling machine, plastic sheet milling machine, acrylic sheet milling machine, jewelry engraving machine, gem engraving machine, ring engraving machine, earring engraving machine, nameplate engraving machine, nameplate engraving machine, nameplate engraving machine, nameplate engraving machine, nameplate engraving machine for sale, mini cnc, create mini cnc, cnc, mini cnc, cnc servo, second hand mini cnc, mini cnc price, mini cnc kit, cheap mini cnc, small cnc machine, engraving machine, cnc engraving machine, cnc engraving machine CNC machines cnc machines mini cnc machines mini cnc mini cnc engraver mini cnc engraving cnccnc engraver cnc engraving cnc engraver machine cnc engraving machine engraver machine engraving machine cncroom cnc lathe cnczone robotech robotech cnc robotech cnc engraver desktop mini cnc desktop cnc cnc rounter cnc rounter machine cnc maker extra cnc salecnc smartcncs build your cnc cnc rounter 3 axis cnc rounter 4 axis cnc 3 axes cnc 4 axes mini cnc 3 axes mini cnc 4 axes cnc 3 axis cnc 4 axis mini cnc 3 axis small cnc machine large cnc machine second hand cnc machine newbie cnc machine mini cnc for sale wood engraving machine plastic engraving machine CNC router cnc milling machine cnc router machine cnc Engraving machine Engraving machine Sign making machine

Introduction: In the fast-paced manufacturing world, improving manufacturing processes is essential to increase efficiency and output quality, and Computer Numerical Control (CNC) machines are tools that allow manufacturers to use cutting-edge technology to precisely control and work with materials and have the ability to automate production. In this article, we will explore the world of CNC machines to understand their functions, benefits, and impact on various industries.

- Advancement of CNC Machines: CNC machines have gained attention and advanced usage from the traditional manufacturing processes which used to be controlled and operated by humans. The use of CNC machines has significantly increased the productivity. These machines come with advanced features that help in perfect manufacturing processes by reducing overruns and increasing productivity.

- Key Features and Functions: CNC machines come in various models and sizes to meet the needs of different industries. These devices have the following key features:

- Computer Controlled: CNC machines use a computer system to control their operations, such as setting and sending commands through the control software.

- Flexibility in customization: CNC machines can be customized to suit different production tasks, with the ability to change tools or customize settings and parameters to suit the user’s needs.

- Accuracy and speed: CNC machines operate at high precision and high speed, allowing manufacturers to produce higher quality products in a shorter period of time.

- Quality Control: Modern machinery is used to control quality in order to detect and eliminate defective products, ensuring that the products exported are of high quality and durable.

- Industrial applications: CNC machines are used in various industries such as:

- Manufacturing and assembly industries: CNC machines are popular for producing complex components and products, such as automobiles, electronic devices, and machinery that involves cutting or turning plastic injection molding.

- Metal fabrication industry: CNC machines are used to make intricate metal tools and parts, such as coating equipment or aircraft parts.

- Furniture Industry: CNC machines are popular for producing modern furniture parts such as tables, cabinets, or complex components.

- Science and Medical Industry: CNC machines are used to produce medical and scientific devices, such as parts for medical instruments or research tools.

- Benefits of CNC Machines: Introducing CNC machines into the manufacturing process offers several benefits for manufacturers:

- Increased Efficiency and Productivity: CNC machines help increase efficiency and productivity by reducing the time spent on manufacturing processes and increasing the production of products.

- Quality and precision: CNC machines can produce parts with high precision and excellent quality to meet customer requirements and production standards.

- Reduce labor costs: CNC machines reduce human involvement in the manufacturing process, resulting in lower labor costs and increased efficiency in resource management and utilization.

- Improved Design and Creativity: CNC machines allow manufacturers to create creative products using sophisticated techniques and the ability to customize and create beautiful and unique pieces.

Summary: CNC machines are important manufacturing tools that are capable of controlling manufacturing processes and producing high-quality, precise products. They are essential tools in industries that require flexible and fast-changing production, such as manufacturing and assembly, metalworking, furniture, and science and medicine. Because of their ability to customize and create products and their increased efficiency, CNC machines are a reference to computer control technology that is used to control the operation of machines that move along the X, Y, and Z axes. The data is entered in the form of binary code that the computer can read and convert into control signals that the machine understands.

CNC machines have many advantages that can solve problems and increase production efficiency:

- Accuracy: CNC machines have high precision in their operation, allowing them to produce workpieces with higher accuracy and quality.

- Production efficiency: CNC machines further automate the manufacturing process, reducing production time and costs.

- Flexibility in customization: CNC machines are easy to customize and change, allowing manufacturers to work with a wide variety of workpieces.

- High Quality Products: CNC machines help produce high quality products and reduce returns or substandard products.

- Saving resources: CNC machines reduce human labor in the manufacturing process, thus reducing labor costs and improving resource efficiency.

- Create Complex Products: CNC machines allow manufacturers to create and produce complex products, providing opportunities to expand the market and offer products that generate more demand.

In summary, CNC machines are tools that automate production, make it efficient, precise, and customizable, allowing manufacturers to produce higher quality products and increase production efficiency.

[/av_textblock]

.png)