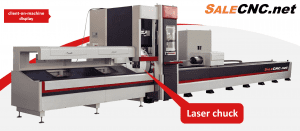

Chuck for CNC Laser Machine

Chuck is used to hold, hold, and rotate workpieces to the correct position specified by the user.

High precision, can be used with workpieces of round steel, square steel, oval and other shapes. Can be applied in a variety of applications.

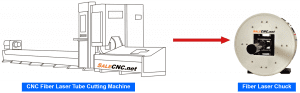

Install chuck on CNC Fiber Laser Tube Cutting Machine

Front chuck – Rear chuck

The back card passes through the front card.hole-cut “zero” tailing

✅ Customized solutions are based on customers.

Customers' needs to design, develop, and fully meet their individual and diverse needs; special components that satisfy customers. Ultra-thin, elongated, heavy spinning type. Fine gripping solution for complex appearance.

✅ Standard customer demand

Worked with a laser cutter manufacturer. The actual needs of standard customers.

✅ Professional R&D team

To form a professional technical team. Characteristic workpiece carry out technical challenge, develop technical scheme, test product execution test.

✅ Product testing

The manufacturer has implemented a bug fix. The test installs the actual site and if there are any testing issues it will be fixed immediately.

✅ Customized solutions based on customers

Customer needs to design, develop and fully meet individual and diverse needs. Special components tailored to customer needs, slim, long and heavy rotation types. Detailed gripping solutions for sophisticated looks.

✅ Customer needs are the main focus.

Working with laser cutting machine manufacturers, products are produced according to the actual needs of customers.

✅Professional R&D team

Establish a professional technical team, the workpiece has specific characteristics, has technical layout development techniques, product testing and product implementation.

✅ Product testing

The manufacturer has implemented bug fixes, real site installation tests, and if there are any problems in testing, they are immediately fixed.

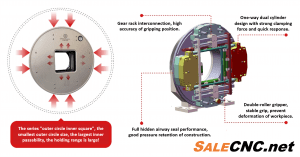

3 chuck technology program

Property : Chuck's properties

✅ The series “outer circle inner square”, the smallest outer circle size, the largest inner passability, the holding range is large!

✅ Gear rack interconnection, high accuracy of gripping position.

✅ Full hidden airway seal performance, good pressure retention of construction.

✅ One-way dual cylinder design with strong clamping force and quick response.

✅ Double-roller gripper, stable grip, prevent deformation of workpiece.

✅ "Outer circle inner circle" series The smallest outer circle size, the largest internal pass, and the holding range are large!

✅ Gear frame connection, high precision of gripping position

✅ Perfect working efficiency, good pressure retention in the structure

✅ Single-acting double cylinder design with strong clamping force and fast response

✅ 2 roller grippers, easy to grip, prevents deformation of the workpiece.

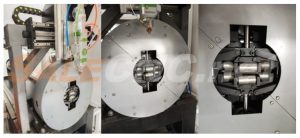

Chuck's working characteristics with different types of workpieces

Chuck sample installed on CNC Fiber Laser (CNC Fiber Laser) FLT-6016L

A good workpiece gripping and rotating system is a strong structure that allows for easy and safe movement of steel.

Specification : Chuck specifications

| Model | DS-110 | DS-170 | DS-240 | DS-350 |

|---|---|---|---|---|

| Claw stroke | 58.5 mm | 90 mm | 120 mm | 110 mm |

| Clamping range | 5-122 mm | 3-183 mm | 13-253 mm | 0-355 mm |

| Diameter | 122 square.hole mm | 183 square.hole mm | 253 square.hole mm | 355 square.hole mm |

| Height | 195 mm | 290 mm | 360 mm | 500 mm |

| Cyclotron precision | 0.05 mm | 0.05 mm | 0.05 mm | 0.05 mm |

| Repeat positioning accuracy | 0.05 mm | 0.05 mm | 0.05 mm | 0.05 mm |

| Barometric pressure range | 0.1-0.6 mpa | 0.1-0.6 mpa | 0.1-0.7 mpa | 0.1-0.8 mpa |

| Rated | 240 r/min | 150 r/min | 130 r/min | 80 r/min |

| Moment of inertia | 0.32 kg.m2 | 3.1 kg.m2 | 6 kg.m2 | 25 kg.m2 |

| Maximum holding force | 100 kg | 250 kg | 300 kg | 800 kg |

| Transmission ratio | 1:1.5 | 1:3 | 1:5 | 1:5 |

| Preservation time | 12 hours | 12 hours | 12 hours | 12 hours |

| Total weight | 37 kg | 100 kg | 230 kg | 480 kg |

| Model | DH-110 | DH-170 | DH-240 | DH-350 |

|---|---|---|---|---|

| Cabua travel distance | 18 mm | 27 mm | 41 mm | 65 mm |

| Holding range | 10-120 mm | 10-170 mm | 10-250 mm | 10-350 mm |

| Center height | 70 mm | 105 mm | 135 mm | 216 mm |

| Cyclotron precision | 0.05 mm | 0.05 mm | 0.05 mm | 0.05 mm |

| Repeat positioning accuracy | 0.05 mm | 0.05 mm | 0.05 mm | 0.05 mm |

| Barometric pressure range | 0.1-0.6 mpa | 0.1-0.6 mpa | 0.1-0.7 mpa | 0.1-0.8 mpa |

| Rated speed of revolution | 240 r/min | 130 r/min | 130 r/min | 80 r/min |

| Rotational inertia | 0.04 kg.m2 | 0.2 kg.m2 | 0.66 kg.m2 | 3.9 kg.m2 |

| Maximum holding power | 80 kg | 180 kg | 240 kg | 500 kg |

| Transmission ratio | 1:1.5 | 1:3 | 1:2.5 | 1:4 |

| Total weight | 32 kg | 68 kg | 137 kg | 440 kg |

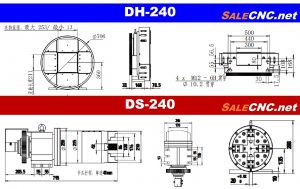

Product structure drawing : Chuck structure drawing

✅ Chuck model DH-110/DS-110

✅ Chuck model DH-170/DS-170

✅ Chuck model DH-240/DS-240

✅ Chuck model DH-350/DS-350

Applications : Examples of work using chucks

Industry Application / Industrial Application

✅ Sheet metal, kitchenware, fitness equipment, elevators, chemicals, electronics, advertising decoration

✅ Automobiles, rail transportation, engineering equipment, construction machinery, environmental protection machinery

Industrial Applications / Industrial Applications

✅ Steel plates, kitchenware, fitness equipment, elevators, chemicals, electrical appliances, advertising decorations

✅ Automobiles, railway transportation, engineering equipment, construction machinery, environmental protection machinery

Add Line: @123wotsb Fern (sales engineer)

Add Line: @123wotsb Fern (sales engineer)  Add Line: @sales Chompoo (sales engineer)

Add Line: @sales Chompoo (sales engineer)

Reviews

There are no reviews yet.