Description

CNC Fiber Laser FB16-1530 3000W

- CNC Fiber Laser FB16 is an intelligent laser capable of cutting all metals. Such as steel, aluminum, copper, brass, stainless steel, silver, titanium and many others.

- Comes with a modern and intelligent controller. Can calculate the shortest distance to cut the material, use the fastest time to save the machine time and the service life of the machine.

- The device also has sensors. And has the fastest torque with the latest 4 Japanese servo motors and driving at 3000 rpm which can run up to 50m / min.

- CNC fiber laser can be used for up to 100,000 hours.

- The machine can choose the color and model.

- We have 500 watts to 2000 watts per customer needs.

- There is also an option for automatic material changing.

Technical Parameter

- Cutting at a maximum speed of 30 m / min

- Cutting thick steel up to 12 mm.

- Cut thick stainless steel up to 5 mm.

- Cut aluminum thickness up to 3 mm.

- Working area size 1.5 x 3 meters

- The machine is very stable, not shaking while running at the highest speed. “Sample video”

- The piece that is cut will have a very beautiful edge.

- Use 3 phase electrical system 380 V.

- If wanting to use the electrical system 220 V. Can be ordered.

Technical Parameter

Software Controller

- Program name: NC Editor

- Easy to use and Highly flexible

- Operating System: Support Windows 7 / Windows 10

- Design File Support: Al, AutoCad, SolidWork, CorelDraw, etc.

- Files support: G Code (*.g ; *.nc)

DXF File (*.dxf)

DWG File (*.dwg)

PLT File (*.plt)

ENG File (*.eng) - Support in 5 languages

– English

– Japanese

– Korean

– Russian

– Chinese - Supports design with all design aids

- Supports 3D design

- The program can do Teaching mode.

- Simulate work before cutting real work

- Find the edge of the work piece.

Quality of Controller

- The controller is designed, developed and researched by professors from MIT Institute, Massachusetts Institute of Technology in the United States of America.

- Able to work at high temperatures

- Supports wireless control

- Use the latest modern architecture

- The latest technology supports the Internet to update firmware.

The quality of the X, Y, Z propulsion unit that we choose for laser machine

- Servo Motor Drive (X, Y, Z) ALPHA Smart, Fuji Electric brand from Japan

- The motor will be all Servo Motor from Japan (Japan).

- Rack & Pinion (Bridge gear) for driving X, Y axis from USA

- Ball Screw for driving Z axis from Germany

Laser Fiber Cutting Head

- Newest Laser Fiber head Able to work 24 hours x 7 days without a break

- Install sensor system to detect objects (such as iron, brass, aluminum)

- Sensor system to prevent head collisions with objects

- Installed another layer of protection sensor with Proximity on the Z axis

- Can adjust the sharpness of the laser light easily Just use your hand to rotate. (Some models

- may require a rotating hex wrench)

- Install water cooling systems from the chiller.

Controller placement for CNC Fiber Laser FB16-1530 1000W

- The controller’s position is at the front of the machine and has a cover (the white cover as in the picture above). If you notice that it is attached to the laser Which will save space In using the machine very much

- For some Fiber Laser models, the controller cabinet is used to install the controller outside, which will greatly depress the work space. Especially those with limited space To position the laser machine

- For “CNC Fiber Laser Model FB-16-1530 1000W” the controller can work in Comfortable high temperatures

- Installed a built-in cooling system, even if the controller is able to operate at high temperatures already.

- The controller is installed with a system to prevent any disturbances that may occur. Especially in the industrial sector with large machinery included

- Controller completely closed Install padlock In order to prevent organisms from entering, such as mice

- Install grounding wire with external connection

Monitor

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/u449-wyjB3A” frameborder=”0″ allow=”accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture” allowfullscreen></iframe>

- The monitor consists of 2 axes, A, B.

- Can rotate 360 ° for A axis

- 180 ° rotation for the B axis

- Mouse & Keyboard & Monitor uses a cable that protects against external interference well.

Remote Control

- Used to control the laser machine with Wireless signal.

- Use instead of controlling via the monitor screen

- Uses dedicated signal-send encryption to prevent external interference

- The structure of the machine is made of the highest quality steel. No problem with twisting

- Weighing more than 4.5 tons, it is a great advantage to make the machine stable and not twisting.

- With a fume extractor while cutting work in closed locations

- Installing a workpiece loading aid

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/eNBhYHWmtb4″ frameborder=”0″ allow=”accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture” allowfullscreen></iframe>

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/HA_oJimZ-Qc” frameborder=”0″ allow=”accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture” allowfullscreen></iframe>

Material that can be cut

Samples

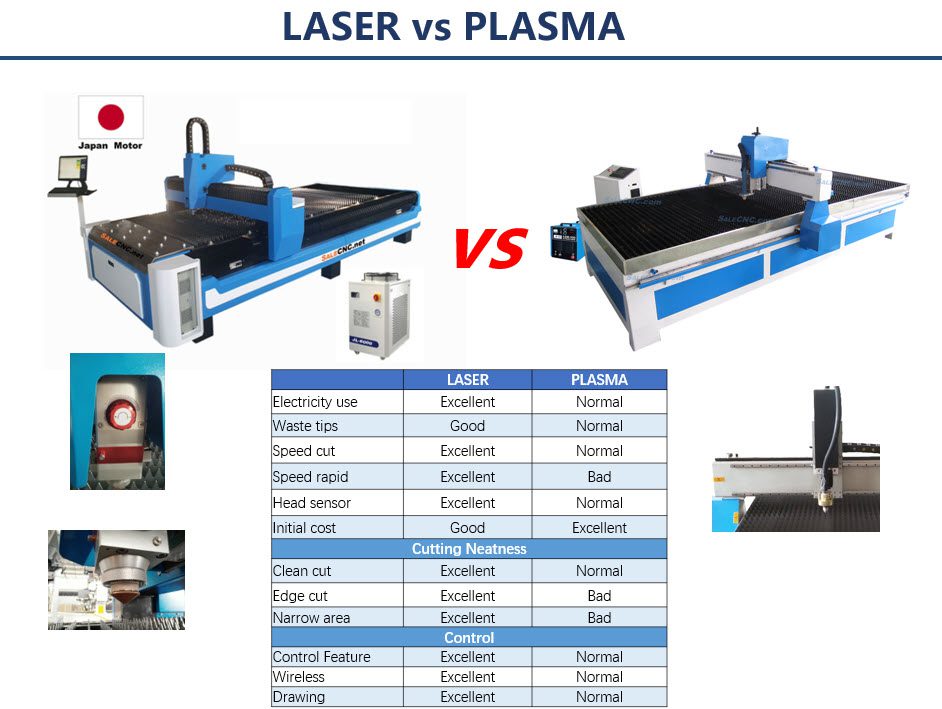

- Electricity use of fiber laser is much lower than plasma. It can be only 20% of plasma use. You can consider 1000W 380V laser is using only 1000W/380V= 2.6A comparing to 60A 380V for plasma source. Many plasma source is using 100A to compared with 1000W (2.6A). You will be surprised the electricity you will be saving when you use laser 6A vs 100A that is 38 times the cost of electricity. For example you are paying 1000USD per month for electricity when you use plasma, then you will only pay about 1000/38=26USD month. That’s a lot of saving.

- Plasma consumption tips, the plasma for one metal plate probably use a lot of tips but fiber laser can use many cutting metal plates for only one laser head tip. Because plasma use high pressure, high volume of air to cut so plasma electrode can burn up fast. One burn up you have to change, the time you change also time for setup and time for machine down. Time machine down is cost of machine and worker’s cost.

- Cutting speed, laser has the very high running speed. The cutting time of fiber laser and plasma probably the same but the free rung the laser can go much faster maybe 10 times faster. Due to the structure of the fiber laser. The machine is very low gravity, the column is very near the table so the machine can run at the very high speed. Unlike the plasma machine, the machine is very tall due to the torch is high. Then the column needs to make it very high so the structure is high, so the machine run can not be fast, otherwise the machine will be shaky.

- Fiber laser has the head sensor much better than the plasma due to the less radiation. Some plasma when they shot, the other electricity machine may black out due to the high radiation of plasma. CNC fiber laser is opposite. It has less radiation and more stability.

1000W Laser Cutting Specification

Material Thickness mm Speed m/min Pressure (Mpa) De-Focus Head Height (mm)

Steel O2 12

Material Thickness mm Speed m/min Pressure (Mpa) De-Focus Head Height (mm)

Stainless N2 3

Material Thickness mm Speed m/min Pressure (Mpa) De-Focus Head Height (mm)

Zinc O2 3

Aluminum N2 3

Copper N2 3

Fiber laser technology has revolutionized the metal cutting industry in recent years. Its exceptional precision and speed, coupled with its low operating cost, make it the preferred choice for many manufacturing applications. However, some people may still wonder if fiber lasers are better than CO2 lasers for cutting metals.

First, let us consider what CO2 and fiber lasers are. CO2 lasers have been used for industrial applications for many years. These lasers emit infrared radiation with a wavelength of 10.6 micrometers, which is well-suited for cutting and engraving materials such as wood, plastic, and paper. Fiber lasers, on the other hand, use a different technology that involves pumping a laser beam through a fiber-optic cable. This creates a laser beam with a much smaller wavelength, typically around 1 micrometer, which is ideal for cutting metals.

According to a recent article on CNC Sourced [1], only industrial CO2 lasers can cut metals. While metals absorb fiber laser beams better than CO2 lasers, they still absorb a portion of the CO2 laser’s beam. Therefore, it is possible to cut metals with a high-power CO2 laser, but it would require a phenomenally powerful 1KW CO2 laser to do so. In contrast, a far weaker fiber laser can cut metal efficiently.

Now, let us explore the advantages of fiber lasers over CO2 lasers in more detail.

- Higher Cutting Speeds

Fiber lasers can cut through metal at much higher speeds than CO2 lasers. This is because the wavelength of the laser beam is shorter, allowing for greater absorption by the material. As a result, fiber lasers can deliver more energy to the cutting surface in a shorter amount of time, enabling faster cutting speeds. This makes fiber lasers an ideal choice for high-volume production environments.

- Better Precision

Fiber lasers also offer higher precision than CO2 lasers. Their smaller beam size and shorter wavelength allow for more accurate cutting of complex shapes and patterns. Additionally, fiber lasers can cut thinner materials with higher accuracy than CO2 lasers. This is particularly important in applications where precise cuts are critical, such as medical device manufacturing.

- Lower Operating Costs

Fiber lasers have lower operating costs than CO2 lasers. This is because fiber lasers use less power and require fewer maintenance and replacement parts. Additionally, fiber lasers do not require any gas, unlike CO2 lasers, which require a constant supply of CO2 and other gases to operate. As a result, fiber lasers are more cost-effective in the long run.

- Reduced Downtime

Another advantage of fiber lasers over CO2 lasers is reduced downtime. Fiber lasers have a longer lifespan than CO2 lasers, and they require less maintenance. Additionally, fiber lasers are less susceptible to damage from environmental factors such as vibration and temperature fluctuations. This means that they require less downtime for repairs and maintenance, ensuring higher productivity and uptime for manufacturing operations.

In conclusion, fiber lasers are a superior technology for cutting metals compared to CO2 lasers. They offer higher cutting speeds, better precision, lower operating costs, and reduced downtime. Therefore, if you are in the market for a laser cutting system for your manufacturing operations, we recommend that you consider a fiber laser over a CO2 laser.

Reviews

There are no reviews yet.