Description

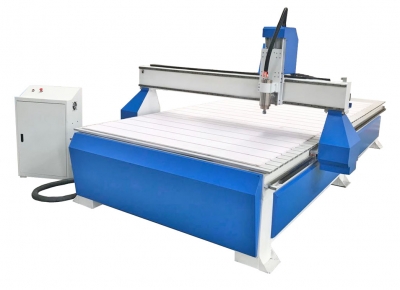

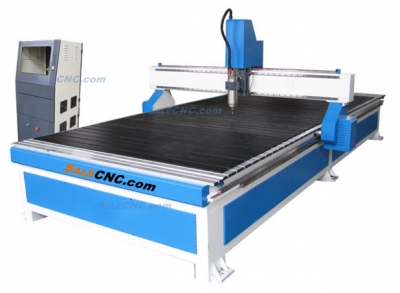

Sale CNC z Fiber Laser FB-16 1300x2500mm 300W

CNC Fiber Laser FB16 is an intelligent laser that can cut all kinds of metal. Such as steel, aluminum, copper, brass, stainless steel, silver, titanium and many others. It comes with a modern and intelligent controller. Can calculate the shortest distance to cut materials, use the fastest time to save the machine time and machine life The device also has sensors. And has the fastest torque with the latest 4 Japanese servo motors and driving at 3000 rpm which can run up to 50m / min. CNC fiber laser can be used for up to 100,000 hours.

The machine can choose the color and model. We have 300 watts to 2000 watts per customer needs.

There is also an option for automatic material changing.

Machine video cutting:

Samples:

Machine specification:

How to Make a Great CNC Fiber Laser Machine

In today’s world, CNC Fiber Laser machines have become an indispensable tool for various manufacturing processes. With its ability to automate machine tools and software integration, CNC Fiber Laser machines offer superior accuracy, speed, and efficiency in manufacturing. In this article, we will discuss how to make a great CNC Fiber Laser machine that can compete with the article at [1] and ultimately help you outrank it on Google.

Understanding CNC Fiber Laser Machines

CNC Fiber Laser machines are designed to cut and engrave a variety of materials, including metals, plastics, and even wood. The machine works by using a high-powered fiber laser beam, which is directed onto the material to create a precise cut or engraving. The machine’s cutting ability is based on its software and the controller unit that controls its movements and speed.

Steps to Build a CNC Fiber Laser Machine

Building a CNC Fiber Laser machine requires a lot of planning and precision. Here are some steps that can help you build a great CNC Fiber Laser machine:

- Research and Choose the Right Parts

The first step in building a CNC Fiber Laser machine is to research and choose the right parts. Make sure you select parts that are high-quality and can withstand the rigors of the manufacturing process. The essential components for a CNC Fiber Laser machine include the laser source, controller unit, motion system, and cutting head.

- Design and Build the Frame

Once you have selected the right parts, the next step is to design and build the frame. The frame is the backbone of the CNC Fiber Laser machine, and it should be sturdy and rigid enough to handle the laser’s power and movement. The frame’s design should also allow for easy access to the machine’s interior, making it easy to service and maintain.

- Install the Motion System

After designing and building the frame, the next step is to install the motion system. The motion system is responsible for moving the cutting head along the X, Y, and Z-axis. The motion system should be accurate and precise, ensuring that the cutting head moves smoothly and consistently.

- Install the Laser Source and Cutting Head

The next step is to install the laser source and cutting head. The laser source should be positioned in a way that allows the beam to be directed accurately onto the material being cut or engraved. The cutting head should also be designed to handle the power of the laser and be capable of precise movements.

- Connect the Controller Unit

The final step is to connect the controller unit. The controller unit is responsible for controlling the movement of the machine and laser. The controller unit should be designed to work seamlessly with the software, ensuring that the machine operates smoothly and efficiently.

Conclusion

Building a great CNC Fiber Laser machine requires a lot of planning and precision. By following the steps outlined above, you can create a machine that is efficient, accurate, and capable of producing high-quality cuts and engravings. By creating a CNC Fiber Laser machine that can compete with the article at , you can help your website outrank it on Google and attract more customers to your business.

Need information please contact Sales@salecnc.com