Fiber laser Cleaning 1,000-3,000W

Rust remover, laser rust remover

Handheld laser cleaning machine, Laser Cleaning Machine Laser cleaning equipment

✅ Handheld laser cleaning machine is a new generation of high-tech laser technology products, non-contact cleaning, does not damage the matrix parts, and the machine components do not contain consumables, which is energy-saving and environmentally friendly.

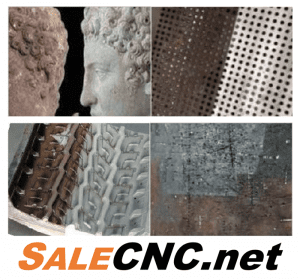

Application of rust remover, laser rust remover, Laser Cleaning Machine 1,000W

Completely remove rust with a rust remover, a laser rust remover, a Laser Cleaning Machine 1,000W.

While shooting 1000w laser

While shooting 1000w laser

It can really shoot out rust and produce quality work.

✅ Effectively removes resin, oil, dirt, rust and corrosion on the surface of the workpiece.

✅ The production of laser rust removal machines, coating, plating and painting meet the cleaning requirements of complex shapes.

✅ Good positioning in the industrial processing field and provides higher cleaning results and lower overall production costs.

✅ Mainly used in automobile manufacturing industry, mechanical processing, electronic processing, cultural relics restoration, mold industry, shipbuilding, food processing, petrochemical industry and other industries.

Can shoot rust in any shape, curved, round, concave, that shape, can reach every point with a rust-cutting laser.

Before rusting curved, concave, and convex surfaces of workpieces

After rusting the workpieces, curved surfaces, concave surfaces, and other surfaces

✅ Laser cleaning technology refers to the use of high-energy laser beams to irradiate the surface of the workpiece to instantly evaporate or peel off the dirt, rust or coating on the surface, and effectively remove the adhesion or surface coating on the surface of the cleaning object at a high speed to achieve a clean process.

✅ Laser cleaning technology refers to the use of high-energy laser beams to irradiate the surface of the workpiece to immediately evaporate or peel off dirt, rust or coatings on the surface, remove adhesion or coatings on the surface, it is an efficient cleaning and high-speed machine for thorough cleaning.

Hand-controlled laser rust removal head, easy to hold, safe and harmless to users.

🔥Laser rust removal on sheet metal, thoroughly cleaning in a short period of time (Laser Cleaning Machine)

✅ It is a new technology based on the interaction effect of laser and matter. It is different from the traditional mechanical cleaning method, chemical cleaning method and ultrasonic cleaning method (wet cleaning process).

✅ It is a new technology that uses the collaboration of laser and material, which is different from traditional mechanical cleaning methods, chemical cleaning methods and ultrasonic cleaning methods.

The laser rust remover is very easy to use! Even women can use it. It has a safety system.

Today, the customer came to see the rust-cutting laser machine, rust-shooting machine, and he really liked it!!👍👍

✅ It does not require any CFC organic solvents that destroy the ozone layer and is pollution-free. , No noise, harmless to human body and environment, it is a kind of “green” cleaning technology. Laser cleaning has obvious advantages compared with traditional cleaning methods.

✅ No need to use any organic solvents CFC that destroy the ozone layer and pollution-free, no noise, no harm to human body and environment, it is a kind of “green” cleaning technology. Laser cleaning has obvious advantages compared to traditional cleaning methods.

The appearance of the machine (appearance around the rust remover machine)

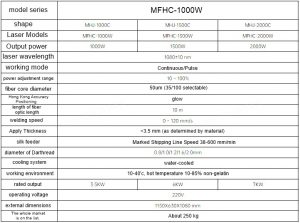

Product specification (Parameters of rust remover)

Fiber laser Cleaning 1000W

✅ Model series : MFHC

✅ Shape : MHJ-1000C

✅ Laser Models : MFHC-1000W

✅ Output power: 1000W

✅ Laser wavelength : 1080±10nm

✅ Working mode : Continuous/Pulse

✅ Power adjustment range : 10-100%

✅ Fiber core diameter : 50um (35/100 selectable)

✅ Hong Kong Accuracy Positioning : glow

✅ Length of fiber optic length : 10m

✅ Welding speed : 0-120mm/s

✅ Apply Thickness : <3.5mm (as determined by material)

✅ Silk feeder : Marked Shipping Line Speed 38-600 mm/min

✅ Diameter of Darthread : 0.8/1.0/1 2/1.6120mm

✅ Cooling system : water-cooled

✅ Working environment : 10-40°C, hot temperature 10-85% non-gelatin

✅ Rated output : 3.5KW

✅ Operating voltage : 220V

✅ External dimensions : 1150x630x1080mm

✅ The whole market is on the list : About 250kg

—-

Fiber laser Cleaning 1500W

✅ Model series : MFHC

✅ Shape : MHJ-1500C

✅ Laser Models : MFHC-1500W

✅ Output power: 1500W

✅ Laser wavelength : 1080±10nm

✅ Working mode : Continuous/Pulse

✅ Power adjustment range : 10-100%

✅ Fiber core diameter : 50um (35/100 selectable)

✅ Hong Kong Accuracy Positioning : glow

✅ Length of fiber optic length : 10m

✅ Welding speed : 0-120mm/s

✅ Apply Thickness : <3.5mm (as determined by material)

✅ Silk feeder : Marked Shipping Line Speed 38-600 mm/min

✅ Diameter of Darthread : 0.8/1.0/1 2/1.6120mm

✅ Cooling system : water-cooled

✅ Working environment : 10-40°C, hot temperature 10-85% non-gelatin

✅ Rated output : 6KW

✅ Operating voltage : 220V

✅ External dimensions : 1150x630x1080mm

✅ The whole market is on the list : About 250kg

—-

Fiber laser Cleaning 2000W

✅ Model series : MFHC

✅ Shape : MHJ-2000C

✅ Laser Models : MFHC-2000W

✅ Output power: 2000W

✅ Laser wavelength : 1080±10nm

✅ Working mode : Continuous/Pulse

✅ Power adjustment range : 10-100%

✅ Fiber core diameter : 50um (35/100 selectable)

✅ Hong Kong Accuracy Positioning : glow

✅ Length of fiber optic length : 10m

✅ Welding speed : 0-120mm/s

✅ Apply Thickness : <3.5mm (as determined by material)

✅ Silk feeder : Marked Shipping Line Speed 38-600 mm/min

✅ Diameter of Darthread : 0.8/1.0/1 2/1.6120mm

✅ Cooling system : water-cooled

✅ Working environment : 10-40°C, hot temperature 10-85% non-gelatin

✅ Rated output : 7KW

✅ Operating voltage : 220V

✅ External dimensions : 1150x630x1080mm

✅ The whole market is on the list : About 250kg

Note: The above performance parameters are standard test data. Due to the complexity of actual applications, the data may vary.

Note: The above performance parameters are standard test data. Actual use data may vary.

Laser rust removal, rust shooting, rust removal 1000W Fiber laser Cleaning

- It is efficient, fast, and low-cost, and the thermal load and mechanical load on the substrate is small, and the cleaning is non-damaging.

- The waste is recyclable, no environmental pollution.

- It is safe and reliable, and does not harm the health of the operator.

- It can remove a variety of different thicknesses and differences Coating of ingredients.

- Fast, efficient, low cost and reduces heat load.

- Can be used on small objects, cleaning does not cause damage.

- Waste can be recycled without causing environmental pollution.

- Safe and reliable, no harm to the health of operators.

- Can remove various thicknesses and coating variations of rust.

Rust Removal Laser Machine Metal Cleaning Laser Machine 100W-200W

Features of laser cleaning machine

- Equipped with Raycus laser, high beam quality and stable performance

- Hand-held laser cleaning head, convenient and easy to use, lightweight and can be used for long-term operations

- Using integrated design, compact structure and easy to install, it can be operated after power on

- Wide range of material applicability, flexible and efficient application in various industrial processing scenarios

- Low requirements for working environment, stable system and maintenance-free, long service life

- Non-contact processing, no consumables, no damage, no pollution

Features of laser cleaning machine

- Equipped with Raycus laser, the beam has high quality and stable performance.

- The handheld laser head is easy to clean, easy to use, light weight, and can be used for a long time.

- Using integrated design, compact structure, easy to install, and can work immediately when turned on.

- Use of durable, flexible and efficient materials for manufacturing in various industrial processing situations.

- The device does not consume a lot of energy, has a stable operation system, and has a long service life.

- Non-contact operation, no consumables, no damage, no pollution.

No more rust problems! Easily remove rust from tools and appliances without sandpaper.

Traditional industrial cleaning

In the fields of petroleum, chemical industry, iron and steel, electric power, etc., due to the production, transportation, storage, installation, and production of new equipment and pipelines, oil stains, welding slag and various oxides will inevitably be generated. Polymers, scale, deposits, rust and corrosion will also be produced. In order to prevent major safety accidents such as leaks and explosions, industrial cleaning is a necessary means. However, there are also some problems in several commonly used industrial cleaning methods :

❌ Mechanical friction cleaning method, high cleanliness, but easy to damage the substrate

❌ Chemical corrosion cleaning method is stress-free cleaning, but the pollution is heavy.

❌ Liquid and solid jet cleaning method is more flexible, but the cost is higher, and the waste liquid treatment is more complicated.

❌ The high-frequency ultrasonic cleaning method has a good cleaning effect, but the size is limited and the cleaned workpiece is dry.

Mechanical friction, Chemical corrosion, Liquid solid jet, High frequency ultrasonic

Traditional industrial cleaning

In the fields of petroleum, chemical industry, iron and steel, electric power, etc., due to the production, transportation, storage, installation and manufacture of new equipment and pipelines, oil stains, welding scale, rust and various oxides will inevitably be generated. Polymer scale, rust stains and corrosion (rust) will be produced. It is important to prevent safety accidents, such as leakage and explosion cleaning in industrial plants. However, there are still some problems in the commonly used industrial cleaning methods, such as:

❌ How to clean with mechanical friction High cleanliness but easy to damage the surface

❌ How to clean chemical corrosion

❌ Liquid and solid jet cleaning methods are more flexible, but more expensive and complex.

❌ High-frequency ultrasonic cleaning method has good cleaning effect, but its size is limited, and the cleaned workpiece must be dry.

Advantages

Laser cleaning technology emerged as a green and environmentally friendly cleaning method. Compared with traditional industrial cleaning, it has the following advantages. It has become an emerging laser cleaning technology that has attracted the attention of automobile manufacturing, electronic processing, mold industry, petrochemical and other industries. :

✅ No consumables, no chemical pollution, no noise, energy saving and power saving

✅ No contact, no grinding, no stress, minimal damage to the substrate

✅ It can remove pollutant particles below nanometer level with high cleanliness.

✅ Optical fiber transmission, movable operation, can be cleaned and difficult to reach parts

✅ Synchronous cleaning and simultaneous processing to achieve zero emissions during the cleaning process

✅ It can realize rapid cleaning of heavy pollutants and high-speed cleaning of light pollutants

Advantages of rust remover

Laser cleaning technology has become an environmentally friendly cleaning method. Compared with traditional industrial cleaning, it has become an emerging laser cleaning technology, which has attracted the attention of automobile manufacturing, electronic processing, petrochemical mold industry and other industries. It has the following advantages:

✅ No consumables, no chemical pollution, no noise and energy saving.

✅ No touch, no grinding, minimal damage to surface

✅ Can eliminate pollutant particles below the nanometer level.

✅ Can clean hard-to-reach parts

✅ Synchronous cleaning and simultaneous processing, achieving zero emissions during cleaning.

✅ Can quickly clean heavy pollution and clean light pollution at high speed.

Rust removal of the grating, rust is stuck tightly, very thick rust, peels off easily in just a few minutes.

Before shooting the grate, there was a lot of rust and it was very sticky.

Comparison before and after shooting laser into the grid

Comparison before and after shooting laser into the grid

Remove the paint from the gas tank, change from sandpaper to laser engraving, save time, save your money✌

Example (Example of use)

✅ Rust removal

✅ Paint stripping

✅ Degreasing polishing

✅ Pretreatment of parts before coating Pretreatment of parts before coating

✅ Pre-weld preparation Preparation before welding

✅ Post-weld treatment Post-weld treatment

✅ Oxide removal removes oxides

✅ Cultural relic restoration Restoration of ancient objects

✅ Aviation industry Aviation industry

✅ Shipbuilding industry Shipbuilding industry

✅ Automotive industry Automotive industry

✅ Construction industry Construction industry

✅ Food processing industry Food processing industry

✅ Tire industry Tire industry

✅ Electronics industry

✅ Cultural relic restoration Restoration of ancient objects

✅ Production and processing industry Production and processing industry

Paint stripping

Before peeling off the paint from spray bottles and paint buckets with a laser rust-etching machine

Before peeling off the paint from spray bottles and paint buckets with a laser rust-etching machine

Before peeling off the paint from spray bottles and paint buckets with a laser rust-etching machine

Before peeling off the paint from spray bottles and paint buckets with a laser rust-etching machine

Remove the paint from spray bottles and paint buckets with a laser rust remover and rust remover (Laser Cleaning Machine)

After peeling off the paint from spray bottles and paint buckets with a laser rust-etching machine

After peeling off the paint from spray bottles and paint buckets with a laser rust-etching machine

Rust removal and rust removal with a rust removal laser machine, metal cleaning Rust Removal Laser Machine

If interested or have questions, call

082-972-9329 (Jimmy)

083-256-5981 (Komin)

02-312-0227 (office)

E-mail : Sales@salecnc.com

Reviews

There are no reviews yet.