Description

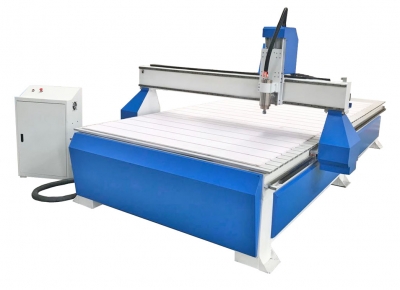

Sale Foam Cutting Machine CX-1330

APPLICATION :

Polyvinyl chloride foam (EPS), polypropylene plastic foam material (EPP), XPS Extrusion board

Mainly for the industry: Foundry industry, advertising industry, film and television props, packaging industry, EPS construction lines, and other industry-specific equipment.

PERFORMANCE CHARACTERISTICS :

The CNC machining machine adopts independent gantry design, gantry can cut benzene board materials in batches. Processing accuracy industry first! All mounting surfaces are machined precisely to ensure accurate operation.

Cutting software CAXA and AUTOCAD drawings with full Chinese operation can be cut without scanning, coding and programming. It also has on-line simulation function. It is very convenient to use and easy to learn.

The transmission system adopts Taiwan-made ball screw and straight-line square rail, with precise transmission without clearance and low noise. It differs from other companies that generally use chains, belts or ordinary fine threaded screw rods. Its service life and precision are vastly different.

The overall design adopts the structure of large-scale NC machine tools, and the whole bed adopts the finishing milling of large-scale five-sided milling processing center to maximize the verticality and horizontality of the equipment.

All the tables are made of 20mm thick high density polyester board, which is milled by the processing center again to ensure the maximum level of the tables, and marked with positioning line and center line, with minimal details.

All the control lines adopt flexible shielded cables, high wear resistance, flame retardant, super flexible and bending resistance.

The control host adopts a brand-new professional industrial computer or DSP handle.

Sample

Parameter

Contact us at Tel.+668 2972 9329 (Jimmy ) E-mail Sales@salecnc.com

Reviews

There are no reviews yet.