Description

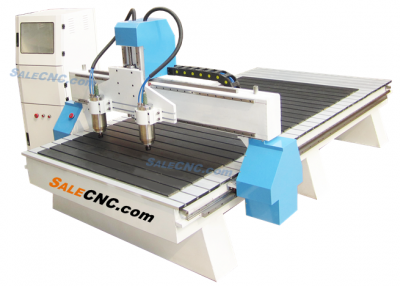

SALE CNC Router Milling รุ่น CX-1325

Cut acrylic machine, Cut plastic, Cut ABS, Cut soft metal, Cut wood

Detail

1. Size 1300 × 2500 millimeters (Working area)

2.Spindle 3.2Kw.

3. stepping motor

4. NC Studio controller

5. Maximum cutting speed 30 Meters/Minute

Controller

Sample Work

How to Make a Good CNC Router: A Step-by-Step Guide

If you’re interested in building your own CNC router, you’re in the right place. A CNC (Computer Numerical Control) router is a versatile machine that can be used for a variety of purposes, including cutting, engraving, and carving. In this article, we will provide a comprehensive guide on how to build a good CNC router from scratch.

Introduction

Before we dive into the details, let’s first discuss the basics of a CNC router. A CNC router is essentially a computer-controlled cutting machine that uses a spindle to cut or carve materials such as wood, plastic, and metal. The machine can be controlled using software, allowing for precise and accurate cuts. Building a CNC router from scratch may seem like a daunting task, but it can be a rewarding experience and ultimately save you money in the long run.

Planning

Before you start building your CNC router, it’s important to have a solid plan in place. This will help you avoid mistakes and ensure that your machine functions properly. Here are some things to consider when planning your CNC router:

Purpose

What will you be using your CNC router for? This will help determine the size and power of the machine you need.

Budget

How much money are you willing to spend on your CNC router? This will also help determine the size and power of the machine you can build.

Design

What design will you use for your CNC router? Will you use an existing design or create your own?

Materials

What materials will you use to build your CNC router? Will you use wood, metal, or a combination of both?

Building Your CNC Router

Now that you have a plan in place, it’s time to start building your CNC router. Here are the basic steps you will need to follow:

Step 1: Frame

The frame is the foundation of your CNC router. It needs to be sturdy and stable to ensure accurate cuts. You can use wood or metal to build the frame, but make sure it’s strong enough to support the weight of the router.

Step 2: Linear Motion

The next step is to add linear motion to your CNC router. This includes the rails and bearings that will guide the machine’s movement. You can use off-the-shelf parts or build your own linear motion system.

Step 3: Motors and Control

Now it’s time to add motors and a control system to your CNC router. The motors will move the machine along the rails, while the control system will ensure precise movements. You can use stepper or servo motors, depending on your needs.

Step 4: Spindle and Tooling

The spindle is the part of the CNC router that holds the cutting tool. You can use a router, spindle, or laser depending on the type of cuts you will be making. You will also need to choose the appropriate tooling for your cutting needs.

Step 5: Wiring and Electronics

The final step is to wire and connect all the electronics. This includes the motors, control system, and spindle. Make sure to follow the manufacturer’s instructions carefully and double-check your work before powering on the machine.

Conclusion

Building a good CNC router takes time, effort, and planning. However, the end result is a powerful machine that can be used for a variety of purposes. By following the steps outlined in this guide, you can build a CNC router that meets your needs and saves you money in the long run.

FAQs

- How long does it take to build a CNC router? Building a CNC router can take anywhere from a few days to several weeks, depending on your experience level and the complexity of the machine.

- Can I use a CNC router to

For more information please contact Sales@salecnc.com

Reviews

There are no reviews yet.